DiVYA

PHONE : +91-8374485833,

Mail : storagetanks@mail.com

INDUSTRIAL PIPING DESIGN CONULTANCY SERVICES

Water Piping Design Services

Piping Design consultants- Water piping |Divya Engineering

WATER PIPING DESIGN AND DRAFTING

Divya Engineering is a consultancy specializing in comprehensive design services for water piping systems. Their offerings encompass detailed CAD drawings, design calculations, pipe stress analysis, 3D modeling, and the preparation of fabrication and erection drawings. They also focus on material selection, support detail design, project management, and ensure compliance with relevant standards such as ASME B31.1 and ASME B31.3.

In addition to water piping systems, Divya Engineering extends its expertise to various sectors, including oil and gas, petrochemicals, and power plants. They offer services like piping layout and routing optimization, piping support design, material selection, stress analysis using tools like CAESAR II, development of Piping and Instrumentation Diagrams (P&IDs), creation of piping specifications and standards, pipe sizing, hydraulic calculations, 3D modeling, and preparation of isometric, fabrication, and erection drawings. For more detailed information or specific inquiries,

WATER PIPING LAYOUT AND ROUTING

Divya Engineering's Water Piping Design Services likely include Piping Layout and Routing, which is an essential aspect of designing water distribution systems for various applications, such as residential, commercial, and industrial settings. This service ensures that water is transported efficiently and safely through the piping network, while considering space constraints, system performance, and ease of maintenance.

Software Tools Used for Piping Layout and Routing

-

AutoCAD: For 2D and 3D design, AutoCAD is typically used to draft water piping layouts and routing plans.

-

Revit: Often used for Building Information Modeling (BIM), which is ideal for complex water piping systems within buildings.

-

Plant 3D: Used for industrial water systems, this software helps in modeling, routing, and optimizing piping systems.

-

CAESAR II: For stress analysis and design validation, ensuring that the system can handle the required pressures and mechanical stresses.

If you’re looking for Divya Engineering’s specific offerings in Piping Layout and Routing, it would be best to contact them directly for a more tailored response to your needs. Let me know if you need more specific details, or if you'd like me to assist with contacting them

WATER PIPING SUPPORT DESIGN

Divya Engineering's Water Piping Design Services likely include Piping Support Design, which is an essential aspect of any piping system, especially in water distribution systems. Proper piping support ensures the system is structurally sound, operates efficiently, and remains safe throughout its lifespan. This service involves designing supports, hangers, and brackets that hold the pipes in place and prevent damage from movement, vibration, thermal expansion, and other forces.

Software and Tools Used in Piping Support Design

-

CAESAR II: Widely used for piping stress analysis and support design. It helps in determining the effects of thermal expansion, mechanical forces, and other loads on the system.

-

AutoCAD Plant 3D: Used for 3D modeling of piping systems, including supports and their integration with the piping layout.

-

Revit: Often used for integrated design in buildings, providing accurate 3D visualization of the entire piping system and its supports.

-

Support Design Software: Specialized software for analyzing and designing pipe supports, hangers, and brackets, ensuring they meet load and performance criteria.

Piping Support Design is crucial for maintaining the long-term integrity and reliability of water piping systems. Divya Engineering’s services would encompass everything from conceptual design and load calculations to the installation and post-installation inspection of supports. They would use advanced software tools to ensure that the support system is robust, cost-efficient, and compliant with industry standards.

WATER PIPING MATERIAL SELECTION

Piping Material Selection is a critical aspect of water piping design services, and Divya Engineering's services likely include helping clients choose the most appropriate materials for their water distribution systems. The right material selection ensures the system is durable, cost-effective, and able to handle the pressures, temperatures, and other conditions it will face during its lifecycle. Here's a breakdown of what Piping Material Selection generally involves in the context of water systems.

Piping Material Selection is a vital part of water piping design, and Divya Engineering would help clients choose the most appropriate materials based on factors like pressure, temperature, corrosion resistance, and cost efficiency. Whether for residential, commercial, or industrial systems, selecting the right material ensures optimal performance and long-term sustainability.

If you’re looking to discuss specific materials for your project or get more detailed recommendations from Divya Engineering,

WATER PIPING STRESS ANALYSIS

Piping Stress Analysis is an essential part of Divya Engineering's water piping design services. It ensures that the piping system is structurally sound and can withstand the operational stresses it will encounter over its lifetime. In water distribution systems, stress analysis helps identify potential issues like thermal expansion, pressure surges, vibration, and mechanical load, which could lead to failures, leaks, or system degradation.

. Industry Standards and Codes for Piping Stress Analysis

Divya Engineering would ensure that their piping stress analysis complies with industry standards, including:

-

ASME B31.3: The standard for process piping systems, detailing the design, materials, and safety considerations for water and industrial piping systems.

-

ASME B31.1: Covers power piping, including steam, water, and other fluid systems under pressure.

Piping Stress Analysis is an essential service offered by Divya Engineering to ensure the safe and efficient operation of water piping systems. It involves assessing how pipes respond to temperature changes, internal pressure, external forces, and dynamic loads. Using advanced software tools like CAESAR II and AutoPIPE, Divya Engineering can optimize pipe layouts, material selection, and support placement to ensure the system is robust, cost-efficient, and compliant with industry standards.

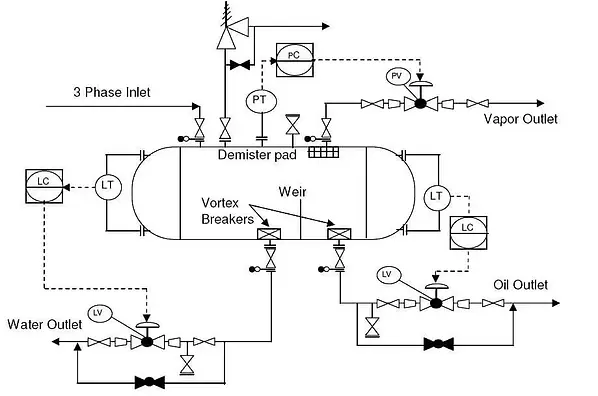

WATER PIPING AND INSTRUMENTATION DIAGRAMS (P&IDS):

Divay Engineering Water Piping design services- PIPING AND INSTRUMENTATION DIAGRAMS (P&IDS):

Piping and Instrumentation Diagrams (P&IDs) are essential tools in the design, operation, and maintenance of water piping systems. Divya Engineering's Water Piping Design Services would likely include the development of P&IDs to ensure clarity in system design, operation, and future troubleshooting.

Piping and Instrumentation Diagrams (P&IDs) in Water Piping Design

1. What are P&IDs?

A Piping and Instrumentation Diagram (P&ID) is a detailed graphical representation of the piping system that illustrates the relationship between pipes, equipment, valves, instruments, and control systems. It shows the flow of fluids through the piping system and includes the major components such as pumps, filters, tanks, and any related instrumentation or control devices.

WATER DEVELOPMENT OF PIPING SPECIFICATIONS AND STANDARDS

When it comes to water piping systems, the development of piping specifications and standards is a fundamental service offered by Divya Engineering. These specifications and standards ensure that the entire piping system is designed, installed, and maintained according to consistent, reliable, and efficient practices. They help guarantee system safety, performance, longevity, and compliance with local and international standards.

How Divya Engineering Develops Piping Specifications and Standards

The development of piping specifications and standards by Divya Engineering typically follows a systematic and phased approach to ensure comprehensive coverage and project success:

Summary

The development of piping specifications and standards is a critical service provided by Divya Engineering for water piping design. These specifications ensure the proper selection of materials, the correct sizing of pipes, and compliance with all necessary codes and safety standards. The goal is to create a piping system that is safe, reliable, cost-effective, and capable of operating efficiently over its lifetime.

WATER PIPE SIZING AND HYDRAULIC CALCULATIONS

Divya Engineering's water piping design services include essential aspects such as pipe sizing and hydraulic calculations, which are critical to ensuring the efficiency, reliability, and longevity of the system. Proper pipe sizing and hydraulic analysis are key to optimizing the performance of water systems, whether for industrial, commercial, or municipal applications.

.

3. How Does Divya Engineering Approach Pipe Sizing and Hydraulic Calculations?

At Divya Engineering, the process of pipe sizing and hydraulic calculations involves a systematic and detailed approach, ensuring that all parameters are carefully considered for optimal system performance:

Pipe sizing and hydraulic calculations are key elements of the water piping design process, ensuring that the system performs efficiently and safely. Through accurate calculations, Divya Engineering can optimize the flow of water, minimize pressure losses, and select the appropriate pipe materials and sizes. These efforts lead to a more cost-effective and sustainable water piping system, ensuring reliability and compliance with industry standards.

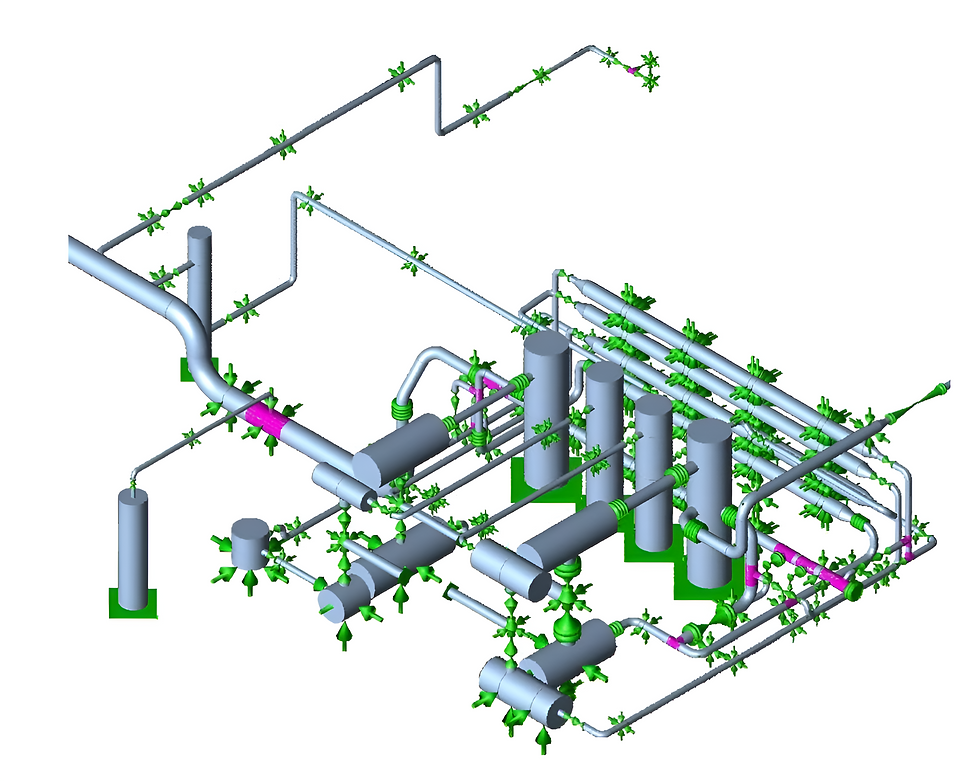

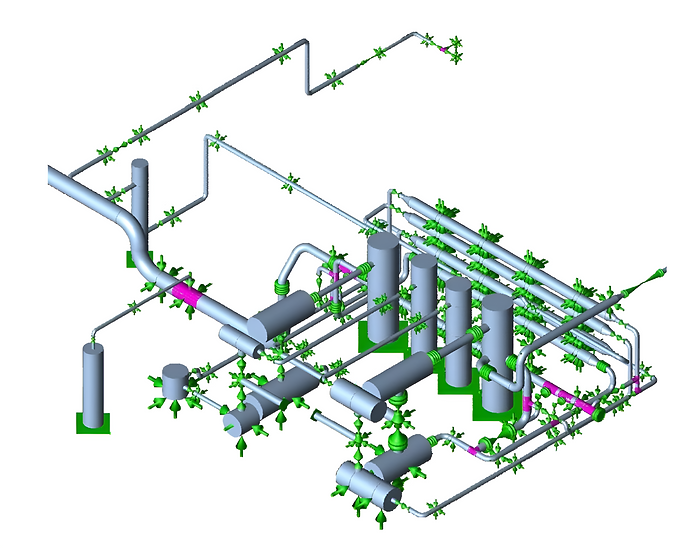

WATER 3D MODELING AND DESIGN

In the field of water piping design, 3D modeling and design play a crucial role in creating efficient, accurate, and visually clear representations of piping systems. Divya Engineering offers advanced 3D modeling and design services to ensure that water piping systems are precisely designed, optimized, and executed without errors or rework.

Summary

3D modeling and design are pivotal in modern water piping system design, and Divya Engineering leverages this technology to optimize the design process, reduce errors, and ensure that the system is efficient, cost-effective, and easy to maintain. The ability to visualize, simulate, and analyze the entire system before construction allows for the identification of potential issues and the creation of a design that performs optimally in real-world conditions.

If you're looking for a detailed and robust 3D design for your water piping system, Divya Engineering has the tools and expertise to bring your project to life. Would you like to explore a specific part of the design process in more detail or discuss how 3D modeling could benefit your project? Let me know how I can assist!

WATER ISOMETRIC/FABRICATION/ERECTION DRAWINGS

At Divya Engineering, the creation of isometric, fabrication, and erection drawings is a crucial part of the water piping design process. These drawings are essential for the successful installation and operation of the water system. They provide clear, accurate, and detailed instructions for the construction team, ensuring that the system is built according to the design specifications and industry standards.

1. What are Isometric, Fabrication, and Erection Drawings?

Isometric Drawings

An isometric drawing is a type of 3D representation of the piping system, drawn at an angle of 30 degrees to the horizontal. It is used to visually convey the layout and orientation of pipes, fittings, valves, and other system components.

-

Purpose: Isometric drawings are essential for conveying complex pipe layouts in a way that is easy to understand, without requiring the viewer to visualize the system in three dimensions.

-

Key Features:

-

Piping System: Shows the piping route from the source to the end points, including branches and connections.

-

Component Placement: Includes valves, fittings, and supports.

-

Pipe Dimensions: Clearly marks pipe sizes, material specifications, and lengths.

-

Flow Direction: Indicates the flow direction of water within the system.

-

Benefits:

-

Easy to Interpret: Since isometric drawings are more visual and less technical than 2D drawings, they are easier for field teams to interpret and implement.

-

Error Reduction: Provides clarity on how the system components fit together, reducing the chances of errors during installation.

Fabrication Drawings

Fabrication drawings are detailed drawings that provide precise instructions for fabricating the piping system and its components, such as pipes, valves, and fittings, before installation. These drawings are essential for manufacturing and assembly of the piping components in a workshop or fabrication facility.

-

Purpose: To provide the necessary details for constructing and assembling individual piping components or assemblies before they are transported to the site for installation.

-

Key Features:

-

Material Specifications: Specifies the materials for each component (e.g., steel, PVC, HDPE).

-

Pipe Lengths: Includes precise lengths for each pipe section.

-

Cutting and Welding Details: Details the cuts, bends, welding locations, and types of joints required for assembling the pipes.

-

Fitting Specifications: Describes the required fittings and connections, such as elbows, tees, and flanges.

-

Benefits:

-

Precision in Manufacturing: Ensures that each component is fabricated to the exact specifications, reducing the need for on-site adjustments.

-

Cost and Time Efficiency: By ensuring all components are fabricated correctly before installation, fabrication drawings help avoid delays or cost overruns during construction.

Erection Drawings

Erection drawings are used for installing the piping system on-site. They provide the assembly sequence, the placement of pipes, supports, and other components, and detailed instructions for erection and installation.

-

Purpose: Erection drawings guide the installation team in assembling the piping system accurately at the construction site.

-

Key Features:

-

Installation Sequence: Specifies the order in which components should be installed to ensure proper alignment and functionality.

-

Support Locations: Marks the positions of pipe supports, hangers, and brackets, ensuring that the pipes are properly supported and aligned.

-

Component Placement: Indicates the precise location of all valves, pumps, and other components.

-

Instructions for Assembly: Provides detailed instructions for assembling components, including welding, bolting, or any other required connection methods.

-

Benefits:

-

Clear On-Site Instructions: Ensures that the installation team has clear, detailed instructions, which reduces the risk of installation errors.

-

Time and Cost Savings: With precise erection drawings, installation is faster and smoother, which helps in meeting deadlines and minimizing costs.

2. How Divya Engineering Creates Isometric/Fabrication/Erection Drawings

At Divya Engineering, the process of creating isometric, fabrication, and erection drawings is done systematically to ensure that the final drawings are both accurate and comprehensive. Here’s an overview of the steps involved:

1. Design Development

The team starts by reviewing the piping system design and 3D model to fully understand the layout, system specifications, and components. This phase involves close collaboration with engineers, clients, and other stakeholders to confirm design details.

2. Creation of Isometric Drawings

-

Software: Divya Engineering uses advanced tools like AutoCAD, Revit, or SolidWorks to create detailed isometric drawings.

-

The isometric drawing is created based on the piping layout and system design, with all components clearly shown in 3D projection.

-

Dimensions and Details: Pipe sizes, material specifications, supports, and component locations are all accurately labeled.

3. Fabrication Drawing Development

-

Using the isometric drawing and 3D model, fabrication drawings are developed. These include precise details on pipe lengths, welding points, joint types, and material specifications.

-

The drawing also includes any special fabrication instructions, such as cutting angles, threading, or welding requirements.

-

BOM (Bill of Materials): Along with fabrication drawings, Divya Engineering creates a comprehensive Bill of Materials (BOM), listing all parts and materials required for fabrication.

4. Erection Drawing Preparation

-

Erection drawings are created with a focus on the installation process.

-

The team provides a clear installation sequence, including the order of assembly and placement of components.

-

Support locations are clearly marked, ensuring proper alignment and minimizing movement or sagging in the pipes once installed.

-

Detailed assembly instructions are provided to ensure the on-site team knows exactly how to connect the pipes and components.

5. Quality Control and Review

-

After drafting the drawings, the team conducts a thorough review and quality check to ensure all dimensions, materials, and connections are accurate and conform to the standards and project requirements.

-

The drawings are then sent to the client and relevant stakeholders for feedback and approval.

6. Final Documentation and Delivery

-

Once approved, the finalized isometric, fabrication, and erection drawings are delivered to the client.

-

These drawings can be updated or revised during construction if any changes occur on-site, ensuring that the system remains fully accurate throughout the installation process.

3. Why Isometric/Fabrication/Erection Drawings Are Important

1. Enhanced Accuracy and Clarity

-

These drawings are the blueprints for constructing and installing the water piping system. They ensure that the components are fabricated, transported, and installed as per the exact specifications, avoiding any errors that could lead to costly delays.

2. Smooth Communication

-

Clear and detailed drawings help the design team, fabricators, and installers communicate effectively. Each team member has a common reference, minimizing misunderstandings and mistakes.

3. Reduced On-Site Modifications

-

With clear fabrication and erection instructions, there is less need for on-the-spot adjustments during installation. This leads to faster project completion times and cost savings.

4. Regulatory Compliance

-

Isometric, fabrication, and erection drawings help ensure that the system is built to comply with local building codes and industry standards, which are critical for safety, performance, and longevity.

5. Cost Efficiency

-

Well-detailed drawings minimize material wastage, avoid over-ordering of parts, and ensure that all components fit together properly, thus reducing unnecessary costs.

4. Tools and Software Used by Divya Engineering

To ensure the highest quality and precision in the isometric, fabrication, and erection drawings, Divya Engineering uses state-of-the-art software tools, including:

-

AutoCAD: Widely used for 2D and 3D design, AutoCAD is essential for creating isometric and detailed piping drawings.

-

AutoCAD Plant 3D: Specialized for piping and plant design, it allows for 3D modeling, isometric drawing generation, and integration with other systems.

-

Revit: Primarily used for building information modeling (BIM), Revit helps create detailed isometric views and integrates the piping system into the overall building design.

-

SolidWorks: Often used for mechanical piping systems and detailed fabrication drawings.

-

Navisworks: Used for clash detection and reviewing the 3D design in detail, ensuring that the isometric drawings correspond accurately to the actual 3D model.

-

BIM 360: A cloud-based collaboration platform to share and review the drawings with all stakeholders for real-time updates and coordination.

Summary

Isometric, fabrication, and erection drawings are integral to the success of any water piping system project. At Divya Engineering, these drawings are meticulously created to ensure the system is built accurately, efficiently, and without errors. By providing clear, detailed, and well-organized documentation, Divya Engineering helps streamline the installation process, reduce costs, and ensure that the water piping system meets all operational requirements.

Water Piping Design Services

Piping Design consultants- Water piping |Divya Engineering

Piping Design and Drafting: Creating detailed CAD drawings and design calculations for Water piping systems used in power plants, refineries, and other industrial facilities.

Pipe Stress Analysis: Performing static and dynamic stress analysis using software like CAESAR II to ensure the Water piping system can withstand operational and environmental stresses.

3D Modeling and Design: Using software such as PDS, PDMS, or Auto Plant to create 3D models of Water piping systems for better visualization and accuracy.

Isometric/Fabrication/Erection Drawings: Preparing detailed drawings for the fabrication and installation of Water piping systems.

Support Detail Drawing Preparation: Designing and detailing the necessary supports for the Water piping system to ensure stability and safety.

Project Management: Managing the entire Water piping design project from initial conceptualization through fabrication and commissioning.

Compliance with Standards: Ensuring that the design complies with relevant standards such as ASME B31.1 for power piping and ASME B31.3 for process piping.

BILL OF MATERIAL, INSULATION & EXPANSION JOINTS

Challenges in Water Piping Design

Designing water piping systems involves several complexities due to the diverse needs and constraints of different industries, environmental factors, and technical considerations. Whether the system is for municipal water distribution, industrial applications, or residential complexes, ensuring efficiency, durability, and safety is essential. Below are some of the key challenges faced in water piping design:

1. Water Pressure Management

One of the primary challenges in water piping design is ensuring consistent water pressure throughout the system. Variations in pressure can lead to inefficient water distribution, reduced flow rates, or even damage to pipes and equipment. Designers must calculate the correct pipe sizes and system configurations to maintain stable pressure, taking into account elevation changes, long distances, and varying demand patterns. Pressure fluctuations can also result from pump cycling or seasonal usage patterns, which must be managed effectively.

2. Pipe Sizing and Flow Analysis

Proper pipe sizing is crucial for ensuring efficient water flow and minimizing energy consumption. Over-sized pipes lead to unnecessary capital costs, while under-sized pipes may cause high friction losses, reduced flow rates, and poor performance. Achieving the optimal balance between pipe size, flow rate, and pressure loss requires detailed hydraulic analysis and modeling. Incorrect sizing can also result in inefficient operation, particularly during peak demand periods or low water flow scenarios.

3. Material Selection

The choice of material for water pipes is influenced by several factors, including the water quality, operating pressure, temperature, and environmental conditions. Common materials such as PVC, ductile iron, steel, and copper each have advantages and limitations. For example, while PVC is cost-effective and resistant to corrosion, it may not be suitable for high-temperature or high-pressure applications. Selecting the right material is crucial for ensuring the longevity, reliability, and safety of the water piping system.

4. Corrosion and Wear

Corrosion is one of the most common problems that affect water piping systems, especially in environments where water contains aggressive chemicals or in regions with high humidity. Corrosion can weaken pipes, leading to leaks, reduced water quality, and costly repairs. The challenge is to design a system that minimizes exposure to corrosive elements by selecting corrosion-resistant materials, applying protective coatings, and ensuring regular maintenance. Additionally, mechanical wear from high flow velocities or abrasive substances in the water must be accounted for during design.

5. Water Quality and Contamination Prevention

Ensuring that the water delivered through the piping system is clean, safe, and free from contamination is a critical consideration in the design process. The design must account for factors such as sedimentation, bacterial growth, and exposure to harmful chemicals or pollutants. Water treatment systems, filters, and backflow prevention devices are often integrated into the design to maintain water quality. Proper sealing and material selection also prevent contamination from external sources or pipe degradation.

6. Thermal Expansion and Contraction

Water pipes are subject to expansion and contraction due to temperature variations, especially in regions with significant seasonal temperature changes. If thermal expansion is not accounted for in the design, it can result in pipe deformation, increased stress on joints, and even pipe rupture. The system must include expansion joints, flexible connections, or other solutions to accommodate these changes and prevent damage.

7. Leakage and Maintenance

Leakage is a major concern in water piping systems, as even small leaks can lead to water loss, increased operational costs, and system inefficiencies. Designing the system with leak prevention in mind, by using high-quality materials, sealing techniques, and monitoring systems, is essential to avoid these issues. Additionally, ensuring that the system is easily accessible for maintenance and inspection without disrupting operations is a challenge, particularly in underground or hard-to-reach installations.

8. Environmental and Site Conditions

Environmental factors such as soil type, groundwater level, seismic activity, and climate can all impact the design and installation of water pipes. For example, pipes laid in areas with high seismic activity may need additional reinforcement to prevent damage during earthquakes. Similarly, extremely cold or hot climates may require insulation to prevent freezing or heat-related expansion issues. Designers must take these external factors into account to ensure the system's durability and reliability.

9. System Expansion and Future Demand

Designing a water piping system that can accommodate future growth and expansion is a significant challenge. As populations grow or industries expand, the demand for water may increase. Anticipating future needs while avoiding over-sizing the system during the initial design phase is a delicate balance. Proper planning for scalability, including designing the system with spare capacity or provisions for future connections, ensures that the system can be upgraded or expanded without significant modifications.

10. Regulatory Compliance and Standards

Water piping systems must comply with various local, national, and international codes and regulations to ensure safety, water quality, and environmental protection. These standards, such as those set by the American Water Works Association (AWWA), ASTM, and local building codes, regulate everything from material selection and installation methods to water quality parameters and system design. Ensuring compliance with these regulations while maintaining system efficiency and cost-effectiveness can be a complex challenge for designers.

11. Energy Efficiency

Water pumping and distribution require significant energy, and energy efficiency is a growing concern in the design of water piping systems. Poorly designed systems that have excessive pressure losses, inefficient pumps, or high-energy consumption can lead to increased operating costs. Incorporating energy-efficient design practices, such as optimizing pump selection, minimizing friction losses, and using variable speed drives, helps to reduce energy consumption and lower operational costs over the long term.

12. Cost Constraints

Water piping system design must often balance performance, safety, and cost. While high-quality materials and state-of-the-art technology may be desirable, they may not always be affordable within the project's budget. Designers must find innovative ways to optimize system design to achieve the desired results while minimizing costs, whether by using cost-effective materials, selecting the most efficient pump systems, or planning for phased installation.

Conclusion

Water piping system design is a highly complex and multifaceted process that requires careful attention to a wide range of factors, including hydraulic efficiency, material selection, environmental considerations, and regulatory compliance. At Divya Design Consultancy, we work diligently to address these challenges and deliver water piping systems that are safe, efficient, reliable, and sustainable. Our team of experts ensures that each system is designed with the specific needs of our clients in mind, helping to mitigate risks and optimize performance while keeping costs manageable.