DiVYA

PHONE : +91-8374485833,

Mail : storagetanks@mail.com

INDUSTRIAL PIPING DESIGN CONULTANCY SERVICES

Steam Piping Design Services

"Looking for top-tier steam piping design consultancy? Divya Engineering delivers custom solutions with a focus on efficiency, safety, and performance for various industrial applications. Our team of world class professionals are thought leaders, creative designers and collaborative partners for our clients’ most challenging projects. – our experience at Divya Engineering spans over 22 years and includes iconic projects throughout the world.

2024 projects completed

45

48

Oil & Gas

Refineries

134

36

Utility piping

"Divya Engineering offers expert steam piping design and drafting services, delivering high-quality, precision-engineered solutions for industrial projects. Trust our professional team to provide customized, efficient piping systems that meet your specifications and standards."

EXPERT STEAM PIPING LAYOUT & ROUTING SOLUTIONS | DIVYA ENGINEERING

"Divya Engineering offers expert steam piping layout and routing solutions, ensuring efficient and reliable designs for industrial systems. Our experienced team delivers tailored piping strategies to optimize flow, reduce costs, and meet project specifications."

MASTERING STEAM PIPING SUPPORT DESIGN WITH DIVYA ENGINEERING

"Master steam piping support design with Divya Engineering. Our expert team ensures optimal support solutions that prevent excessive stress, vibration, and system failure, enhancing the reliability and longevity of your industrial piping systems."

ACCURATE STEAM PIPE SIZING & SCHEDULING BY DIVYA ENGINEERING

"Divya Engineering specializes in accurate steam pipe sizing and scheduling, ensuring optimal performance and efficiency for your industrial projects. Our expert team delivers reliable, customized solutions to meet your specific requirements and project timelines."

PIPING STRESS ANALYSIS

"Divya Engineering offers comprehensive steam piping stress analysis services to identify potential issues and ensure system integrity. Our expert team uses advanced techniques to analyze, design, and optimize piping systems for maximum safety and efficiency."

Piping Stress Analysis: Performing static and dynamic stress analysis using specialized software like CAESAR II to assess how the steam piping system will respond to both operational and environmental stresses. This process helps identify potential areas of failure and ensures that the steam piping system remains structurally sound under varying conditions

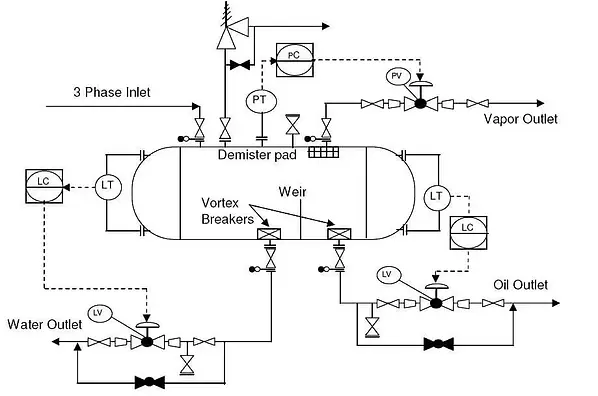

PIPING AND INSTRUMENTATION DIAGRAMS (P&IDS):

Piping and Instrumentation Diagrams (P&IDs): Developing P&IDs to provide a clear representation of the steam piping system, including all components, instrumentation, and control systems. These diagrams serve as essential tools for ensuring proper integration of the system's functions and are a vital reference during both construction and operation phases

DEVELOPMENT OF PIPING SPECIFICATIONS AND STANDARDS

Development of Piping Specifications and Standards: Creating detailed specifications and standards for the selection, fabrication, and installation of steam piping systems. These standards ensure consistency, quality, and compliance with industry regulations, helping to streamline the entire project from design through to commissioning

PIPE SIZING AND HYDRAULIC CALCULATIONS

Pipe Sizing and Hydraulic Calculations: Calculating the appropriate steam pipe sizes and conducting hydraulic analysis to achieve desired flow rates while minimizing pressure drops. This step ensures that the system operates efficiently and within the design parameters while reducing energy costs and potential system failures.

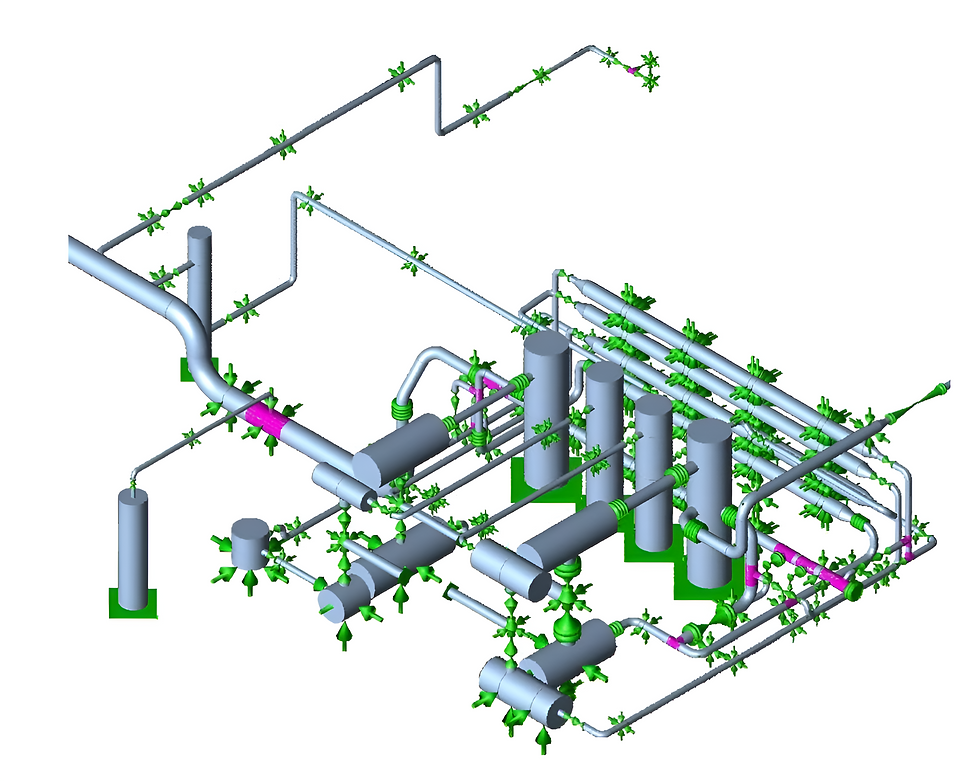

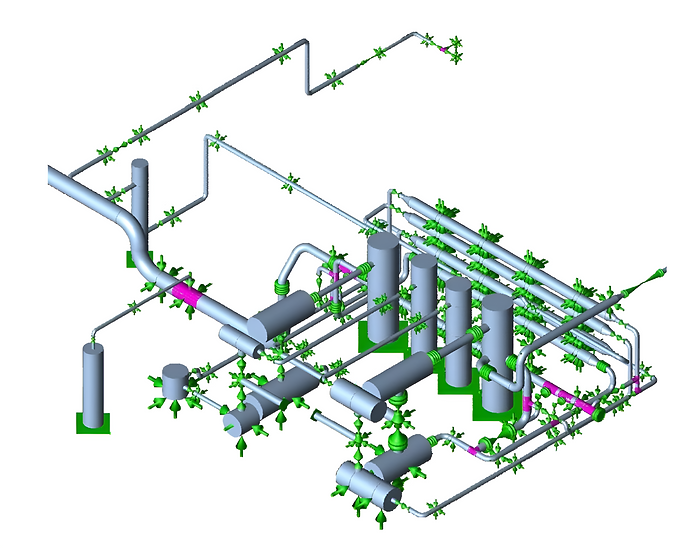

3D MODELING AND DESIGN

3D Modeling and Design: Utilizing software such as PDS, PDMS, or AutoPlant to create detailed 3D models of steam piping systems. These models provide a better visualization of the system layout and help improve accuracy, coordination, and efficiency in the design process, minimizing errors and conflicts during construction.

ISOMETRIC/FABRICATION/ERECTION DRAWINGS

Isometric/Fabrication/Erection Drawings: Preparing detailed isometric, fabrication, and erection drawings that guide the manufacturing and installation of steam piping systems. These drawings ensure that the system is built according to design specifications and that all components are properly aligned for efficient installation.

Karbonn Steel piping

Liquid nitrogen piping

Crude oil piping

Distillation Column Piping

Flare piping

Double Containment and Lined Piping

CNG Piping.

Gas Transmission and Distribution Piping