DiVYA

PHONE : +91-8374485833,

Mail : storagetanks@mail.com

INDUSTRIAL PIPING DESIGN CONULTANCY SERVICES

PUMPS Piping Design Services

Piping Design Consultants- Pumps Piping System | Divya Engineering

A pumps piping system refers to the entire setup that involves the use of pumps for transferring liquids or gases through pipes. These systems are common in industries such as water treatment, chemical processing, oil and gas, HVAC, and more. Here's an overview of key components and considerations:

Key Components of a Pumps Piping System:

-

Pump:

-

Centrifugal Pumps: These are the most common type. They use rotational energy to move fluids through the pipes.

-

Positive Displacement Pumps: These pumps move a fixed volume of fluid per cycle, regardless of system pressure.

-

Diaphragm Pumps: Used for slurries and viscous fluids.

-

-

Piping:

-

Pipes carry the liquid or gas. Material selection for pipes is critical and depends on the type of fluid being transported (e.g., steel, PVC, stainless steel).

-

Pipe Fittings: Used to connect and change direction (elbows, tees, reducers, etc.).

-

Flanges and Valves: For connecting sections of piping and controlling fluid flow.

-

-

Valves:

-

Shut-off Valves: To stop the flow when maintenance is needed.

-

Check Valves: Prevent backflow, ensuring the fluid flows in one direction.

-

Control Valves: Used to regulate the flow rate or pressure.

-

-

Strainers:

-

Prevent debris from entering the pump or causing blockages in the pipes.

-

-

Pressure Relief Devices:

-

These are important to prevent overpressure situations in the system, which could cause equipment failure.

-

-

Flow Meters and Gauges:

-

These are used to monitor the flow rate and pressure of the system, ensuring it operates within safe parameters.

-

-

Supports and Anchors:

-

Proper support structures (e.g., brackets, hangers) ensure the piping is secure and does not move, minimizing stress on the system.

-

-

Expansion Joints:

-

Compensates for thermal expansion or vibration in the pipes due to temperature changes or pump operation.

-

Considerations in Design:

-

Flow Rate & Pressure: The pump needs to meet the system's requirements for pressure and flow rate. This is calculated based on the pipeline length, fluid properties, and system design.

-

Head Losses: The friction in the pipes, fittings, and valves can reduce the system's overall efficiency. Engineers use the Darcy-Weisbach equation or similar methods to calculate head losses.

-

Pump Selection: Proper sizing and selection of pumps based on the system’s needs (flow rate, head, type of fluid).

-

Safety and Maintenance: Regular checks and proper design for ease of maintenance are essential. Also, safety valves and bypass lines should be considered to handle emergencies.

-

System Efficiency: Energy consumption and efficiency should be optimized to reduce operational costs. Proper selection of pumps and control mechanisms plays a key role here.

-

Piping Layout: The layout should minimize sharp bends, as they can cause additional resistance, increasing energy consumption and causing wear on the system.

Example Applications:

-

Water Treatment: Pumps in a water treatment plant will move water through filters, chemical dosing units, and sterilizers.

-

Chemical Process Industry: Pumps move hazardous liquids through reactors and separators.

-

Oil and Gas: Pumps transport crude oil, gas, or water for enhanced oil recovery processes.

"Divya Engineering offers expert piping design consultancy services specializing in Pumps Piping systems. We provide innovative and cost-effective solutions tailored to your project needs

PUMPS PIPING DESIGN AND DRAFTING

Divya Engineering is a consultancy dedicated to providing expert design services for pump piping systems. Their offerings encompass creating detailed CAD drawings, conducting design calculations, performing pipe stress analysis, and developing 3D, along with fabrication and erection drawings. The team focuses on critical aspects such as material selection, support detail design, and project management while ensuring adherence important standards like ASME B31.1 and ASME B31.3. In addition to pump systems, Divya Engineering caters to various industries, including oil and gas, petrochemicals, and power generation, offering services that include piping layout optimization, support design, stress analysis with CAESAR II, and the creation of Piping and Instrument Diagrams (P&IDs), among others.

PUMPS PIPING LAYOUT AND ROUTING

Divya Engineering's Pump Piping Design Services encompass a range of essential offerings, including Piping Layout and Routing. This service is crucial for the effective design of pump distribution systems across residential, commercial, and industrial applications. It guarantees the safe and efficient transportation of fluids through the piping network while addressing space limitations, optimizing system performance, and facilitating maintenance. **Tools Used for Piping Layout and Routing** - AutoCAD: Utilized both 2D and 3D design, AutoCAD is commonly employed to create pump piping layouts and routing plans. - Revit: This software is ideal for Building Information Modeling (BIM), particularly for intricate pump piping systems within structures. - Plant 3D: Designed for industrial pump systems, Plant 3D assists in modeling routing, and optimizing piping configurations.

PUMPS PIPING SUPPORT DESIGN

Divya Engineering's Pump Piping Design Services encompass a range of essential components, including Piping Support Design. This critical aspect of any piping system, particularly within pump distribution frameworks, ensures structural integrity, operational efficiency, and safety throughout the system's lifespan. The service focuses on creating robust supports, hangers, and brackets that secure the pipes, protecting from potential damage caused by movement, vibration, thermal expansion, and other external. To achieve this, advanced software tools such as CAAR II for piping stress analysis and support design, AutoCAD Plant 3D for 3D modeling layout integration, and Revit for precise 3D visualization in integrated designs are utilized.

PUMPS PIPING MATERIAL SELECTION

Piping Material Selection is a critical aspect of pump piping design, and Divya Engineering's services likely include assisting clients in choosing the most suitable materials for their pump distribution systems. Proper material selection ensures that the system is durable, efficient, and capable of withstanding the pressures, temperatures, and other conditions it will encounter throughout its lifecycle. Typically, Piping Material Selection involves evaluating factors such as pressure, temperature, resistance, and cost efficiency. Whether for residential, commercial, or industrial, selecting the right materials guarantees optimal performance and long-term sustainability. you’d like to discuss specifics for your projects, feel free to reach out.

PUMPS PIPING STRESS ANALYSIS

Piping stress analysis is a crucial component of Divya Engineering's *PUMP* piping design services. This analysis ensures that the system is structurally robust and capable of withstanding the operational stresses it will encounter throughout its. In *PUMP* systems, stress analysis plays a vital role in identifying potential such as thermal expansion, pressure surges, vibrations, and mechanical loads, which could lead to failures, leaks, or degradation of the system. **Industry Standards and Codes for Piping Stress Analysis** Divya Engineering adheres to industry standards during their piping stress analysis, including: - **ASME B31.3:** This standard pertains to process piping systems, outlining the necessary design, materials, and considerations for *PUMP* and industrial piping systems. - **ASME B31.1:** This code addresses power piping, encompassing steam, *PUMP*, and fluid systems.

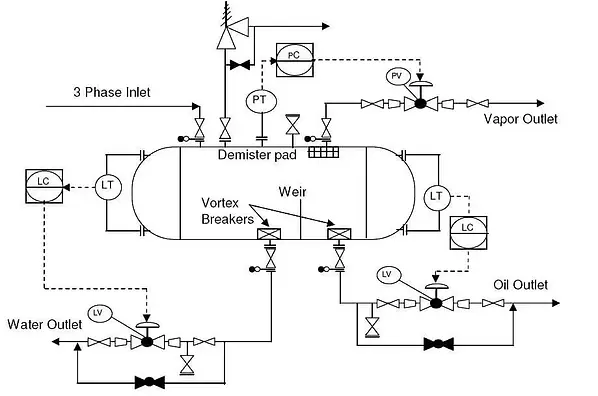

PUMPS PIPING AND INSTRUMENTATION DIAGRAMS (P&IDS):

Divay Engineering Pump Piping Design Services - Piping and Instrumentation Diagrams (P&IDs): Piping and Instrumentation Diagrams (P&IDs) are essential tools in the design, operation, and maintenance of pump piping systems. Divay Engineering's Pump Piping Design Services include development of P&IDs that provide clarity in system design, operation, and future troubleshooting. So, what are P&IDs? A Piping and Instrumentation Diagram (P&ID) is a detailed graphical representation of a piping system that illustrates the relationships between pipes, equipment, valves, instruments, and control systems. It showcases the flow of fluids through the piping system and features major components such as, filters, tanks, and any related instrumentation or control devices.

PUMPS DEVELOPMENT OF PIPING SPECIFICATIONS AND STANDARDS

When it comes to PUMP piping systems, the development of piping specifications and standards is a fundamental service by Divya. These specifications and standards ensure that the entire piping system is designed, installed, and maintained according to consistent, reliable, and efficient practices. This process helps guarantee system safety, performance, longevity, and compliance with both local and international standards. Divya Engineering employs a systematic and phased approach in developing these specifications and standards to ensure comprehensive coverage and project success, making this service critical for PUMP piping design, ensuring proper material selection, accurate pipe sizing, and adherence to local regulations.

PUMPS PIPE SIZING AND HYDRAULIC CALCULATIONS

ya Engineering's PUMP piping design services encompass critical elements such as pipe sizing and hydraulic calculations, which are vital for ensuring the efficiency, reliability, and longevity of the system. Proper pipe sizing and hydraulic analysis are essential to optimizing the performance of PUMP systems across industrial, commercial, and municipal applications. Atya Engineering, we adopt a systematic and detailed approach to pipe sizing and hydraulic calculations, carefully considering all parameters to achieve optimal system performance. Through accurate calculations, we can enhance flow efficiency, minimize pressure losses, and select the most suitable materials for PUMP applications.

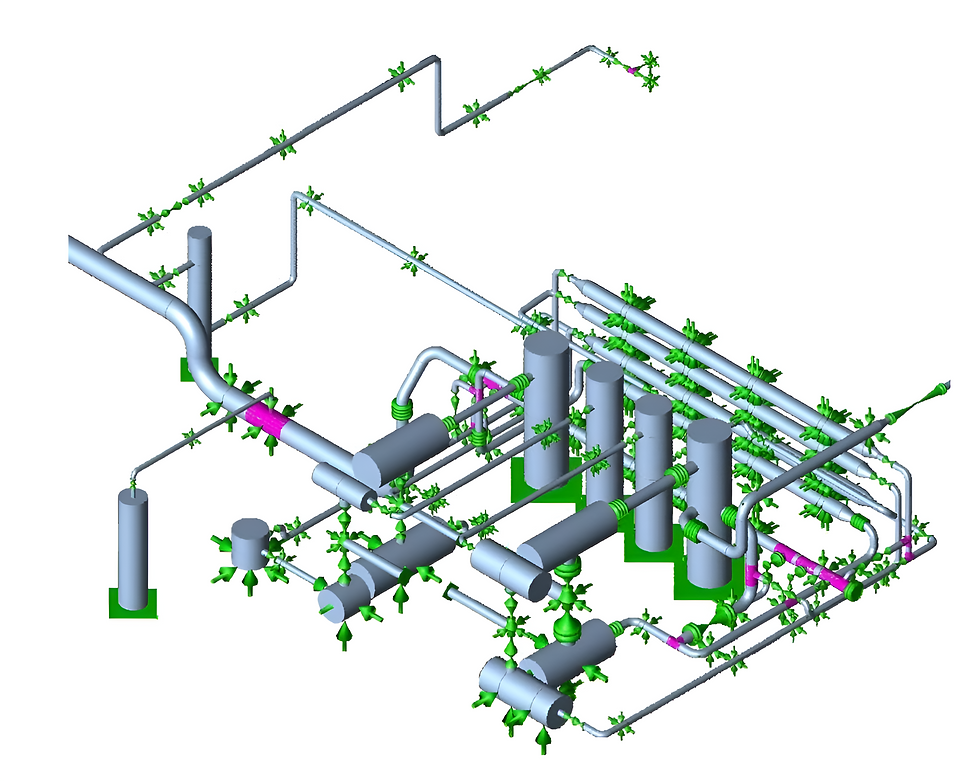

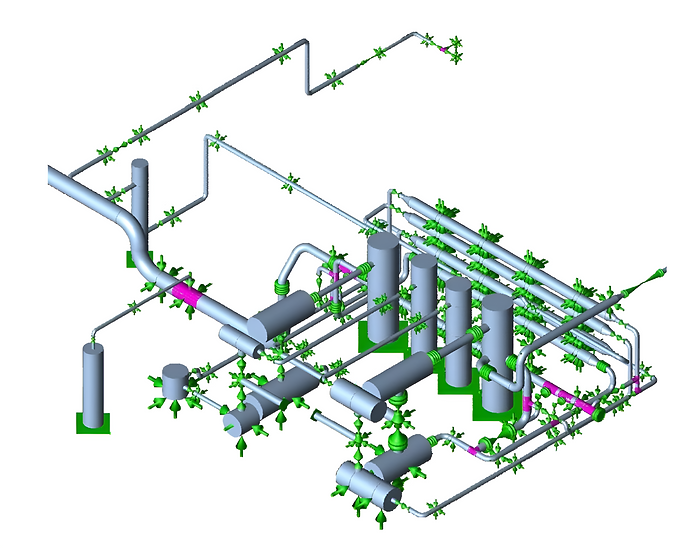

PUMPS 3D MODELING AND DESIGN

In the field of PUMP piping design 3D modeling is essential for creating efficient, precise, and visually clear representations of piping systems. Divya Engineering offers advanced 3D modeling and design services to ensure that PUMP piping systems are meticulously designed, optimized, and executed flawlessly, minimizing the risk of errors or rework. 3D modeling and design play a pivotal role in modern P piping system design, allowing Divya Engineering to enhance the design process, reduce errors, and guarantee that the system is efficient, cost-effective, and easy to implement The capability to visualize, simulate, and analyze the entire system before construction enables the identification of potential challenges and the of a design that performs optimally under real-world conditions. If you're in need of a comprehensive and robust 3D design for your PUMP piping system, Divya Engineering is here to assist you.

PUMPS ISOMETRIC/FABRICATION/ERECTION DRAWINGS

At Divya Engineering, the creation of isometric, fabrication, and erection drawings is a crucial part of the pump piping design process. These drawings are essential for the successful installation and operation of the pump system. They provide clear, accurate, and detailed instructions for the construction team, ensuring that the system is built according to design specifications and industry standards. 1. What are Isometric, Fabrication, and Erection Drawings? Isometric Drawings: An isometric drawing is a type of 3D representation of the piping system, drawn at an angle of 30 degrees to the horizontal. It visually conveys the layout and orientation of pipes, valves, and other system components. Purpose: Isometric drawings are vital for presenting complex pipe layouts in an easy-to-understand format, allowing viewers to visualize the system in three dimensions.

Pumps Piping Design Services

Piping Design Consultants- Pumps Piping | Divya Engineering

Piping Design and Drafting: Creating detailed CAD drawings and design calculations for Pumps piping systems used in power plants, refineries, and other industrial facilities.

Pipe Stress Analysis: Performing static and dynamic stress analysis using software like CAESAR II to ensure the Pumps piping system can withstand operational and environmental stresses.

3D Modeling and Design: Using software such as PDS, PDMS, or Auto Plant to create 3D models of Pumps piping systems for better visualization and accuracy.

Isometric/Fabrication/Erection Drawings: Preparing detailed drawings for the fabrication and installation of Pumps piping systems.

Support Detail Drawing Preparation: Designing and detailing the necessary supports for the Pumps piping system to ensure stability and safety.

Project Management: Managing the entire Pumps piping design project from initial conceptualization through fabrication and commissioning.

Compliance with Standards: Ensuring that the design complies with relevant standards such as ASME B31.1 for power piping and ASME B31.3 for process piping.

BILL OF MATERIAL, INSULATION & EXPANSION JOINTS

Challenges in Pump and Piping System Design

Designing pump and piping systems involves addressing a range of technical and operational challenges. These systems are fundamental in ensuring efficient fluid transport, pressure management, and system reliability across industries such as manufacturing, energy, chemical processing, water treatment, and HVAC systems. Proper design is essential to ensure the system’s functionality, cost-effectiveness, and safety over its operational life. Below are some of the key challenges involved in pump and piping system design:

1. Hydraulic Design and Sizing

One of the primary challenges in pump and piping system design is accurately sizing the pump and piping to meet the required flow rates, pressures, and system conditions. Incorrect sizing can lead to inefficiencies, such as cavitation (in pumps), excessive energy consumption, or operational failure. Achieving the right balance of flow capacity and pressure while ensuring the system operates efficiently at varying loads requires sophisticated calculations and simulations.

2. Energy Efficiency

Pumping systems often consume a significant amount of energy, and optimizing the system for energy efficiency is a major challenge. Proper selection of pump types, control strategies, and piping layout can minimize energy losses. Designers must also consider the impact of system friction, pressure losses, and pump performance curves to ensure the system operates at its best energy efficiency point.

3. Pressure Control and Surge Management

Pressure fluctuations, or water hammer, can be a major issue in pump and piping systems, particularly when pumps are started, stopped, or throttled. These sudden pressure surges can damage pipes, joints, valves, and pumps, leading to costly repairs and system downtime. Designing effective surge control systems, such as pressure relief valves, surge tanks, or soft starters, is crucial to protecting the integrity of the system.

4. Material Selection and Compatibility

Choosing the right materials for both pumps and piping is vital to ensure long-term performance, durability, and safety. Materials must be compatible with the fluid being transported, whether it’s water, chemicals, oil, or gases. In some cases, the fluid’s temperature, viscosity, corrosiveness, or abrasiveness can require special coatings, linings, or material types, adding complexity to the design process. Selecting materials that can handle these conditions without degrading or corroding is essential.

5. Corrosion and Wear

Piping systems and pumps are often exposed to harsh environments, which can lead to corrosion, erosion, or wear over time. For example, pumps that transport abrasive fluids or fluids with high particulate content can suffer from wear and tear, reducing their efficiency and lifespan. Similarly, piping systems can corrode, particularly in chemical or high-temperature applications. Designers must take into account the environmental conditions and select corrosion-resistant materials or protective coatings to prevent premature system failure.

6. Space Constraints and Layout

The physical space available for installing pumps and piping systems can impose design limitations. In many cases, there are tight space constraints that require the system to be compact, which can affect pipe routing, pump placement, and overall system configuration. Efficient layout design, including appropriate use of vertical and horizontal space, can help optimize flow paths and minimize pressure losses, while maintaining ease of access for maintenance and repairs.

7. Thermal Expansion and Contraction

Piping systems can experience significant thermal expansion or contraction as a result of temperature changes. As fluids flow through pipes, the temperature of the system may fluctuate, causing the pipes to expand or contract. This can lead to stress on joints, valves, and other components, potentially causing damage or leakage. Proper consideration of expansion loops, flexible connectors, or expansion joints is necessary to mitigate these effects and maintain system integrity.

8. Pump Cavitation

Cavitation is a common issue in pump systems, where vapor bubbles form in the fluid due to low pressure in certain areas of the pump. When these bubbles collapse, they generate shock waves that can cause severe damage to the pump’s internal components, leading to reduced efficiency and potential failure. Ensuring proper pump selection, maintaining adequate inlet pressure, and designing for optimal flow conditions are essential to preventing cavitation.

9. Vibration and Noise Control

Pumps and piping systems can generate vibrations and noise, particularly under high flow or pressure conditions. These vibrations can cause fatigue in both the pump and piping components, leading to premature failure. Additionally, excessive noise can be a concern for health and safety. To manage these challenges, proper mounting and support systems are needed, including vibration isolation and damping techniques. Noise-reducing designs, such as silencers or mufflers, may also be necessary, especially in sensitive environments.

10. System Integration

Pump and piping systems often need to be integrated into larger, more complex systems. This could include connections to other piping networks, control systems, instrumentation, and automation. Ensuring compatibility between all system components is crucial for achieving optimal performance. For example, control valves, flow meters, and pressure sensors must work in unison to regulate and monitor the system effectively. Integration challenges can also arise when retrofitting new pumps and piping into existing infrastructure.

11. Maintenance and Access

Ongoing maintenance is crucial to ensuring the long-term functionality of pump and piping systems. Proper design must take into account accessibility for inspection, repair, and replacement of parts such as pumps, valves, and pipes. Regular maintenance helps to avoid downtime and costly repairs. Designers must ensure that systems are designed for easy access to critical components and incorporate features such as quick-release valves and maintenance ports to facilitate routine checks.

12. Compliance with Standards and Regulations

Pump and piping systems must comply with local, national, and international standards and regulations related to safety, environmental impact, and operational performance. These standards can vary widely depending on the industry and geographical location. Ensuring compliance with these regulations, including those for pressure ratings, leak prevention, and safety protocols, is a significant challenge that requires close attention to detail and ongoing review of legal requirements.

Conclusion

Designing pump and piping systems requires a deep understanding of fluid mechanics, material science, safety protocols, and operational requirements. The challenges outlined above highlight the importance of precision and expertise in ensuring the systems perform optimally, are safe, and maintain cost-efficiency over time. By addressing these challenges through careful design and strategic planning, pump and piping systems can achieve maximum operational efficiency, safety, and longevity.