DiVYA

PHONE : +91-8374485833,

Mail : storagetanks@mail.com

INDUSTRIAL PIPING DESIGN CONULTANCY SERVICES

Hydrogen Piping Design Services

Piping Design Consultants- Hydrogen Piping | Divya Engineering

"Divya Engineering offers expert piping design consultancy services specializing in hydrogen Piping systems. We provide innovative and cost-effective solutions tailored to your project needs

Hydrogen piping systems are critical infrastructure components in the transport and distribution of hydrogen, particularly in hydrogen-powered industries, fuel cells, and as part of the transition to a low-carbon economy. Given the unique properties of hydrogen, such as its small molecular size, low viscosity, and tendency to embrittle certain materials, hydrogen piping systems require special design considerations.

Here are some key factors to consider in hydrogen piping systems:

1. Materials

-

Stainless Steel: Often used for hydrogen piping due to its resistance to corrosion and strength. However, hydrogen can cause embrittlement in certain stainless steels, so careful material selection and maintenance are crucial.

-

Carbon Steel: This material is less expensive but more prone to hydrogen embrittlement, so it is typically used in low-pressure systems or systems that are treated or coated to mitigate this.

-

Copper: While it is an excellent conductor, it can also suffer from hydrogen embrittlement. It’s less common for large-scale hydrogen systems but may be used in specific applications.

Polymer-based pipes (like PEEK or PVDF) are also emerging options, though typically more for low-pressure or specialized applications.

2. Hydrogen Embrittlement

-

This is one of the primary concerns in hydrogen piping systems. Hydrogen molecules can penetrate metal structures and cause them to become brittle over time, weakening the material and leading to potential failures.

-

Material selection, proper heat treatment, and frequent inspections are necessary to avoid embrittlement and cracks.

3. Pressure Ratings

-

Hydrogen is typically stored and transported at high pressures (up to 700 bar or 10,000 psi in some cases for compressed hydrogen storage).

-

The piping system must be rated to handle these high pressures, and safety factors need to be incorporated into the design to account for pressure surges and fluctuations.

4. Leakage and Sealing

-

Hydrogen molecules are very small, making it challenging to prevent leaks. The piping system should have tight seals, with special attention paid to valves, fittings, and welds.

-

Leaks can be detected using hydrogen-specific leak detection methods, including sniffers and sensors that detect hydrogen concentrations.

5. Temperature Considerations

-

Hydrogen can be used in a variety of temperature ranges (from cryogenic liquid hydrogen at -253°C to high-temperature gaseous hydrogen).

-

Proper insulation and materials that can handle extreme temperatures are important, particularly in cryogenic or high-pressure systems.

6. Corrosion Resistance

-

Hydrogen reacts with oxygen and can cause corrosion in some materials, which may accelerate in the presence of moisture. Proper coatings, corrosion-resistant alloys, and dry environments are necessary for longevity.

7. Design Standards

-

Hydrogen piping systems must meet international standards such as ISO 14687 (for hydrogen quality) and specific codes from organizations like ASME (American Society of Mechanical Engineers), ASHRAE, and others.

-

Codes for pipelines often specify wall thickness, welding procedures, inspection protocols, and safety requirements to ensure safe operation.

8. Safety Considerations

-

Hydrogen’s flammability: Hydrogen is highly flammable and has a low ignition energy. Adequate ventilation, explosion-proof equipment, and safety protocols (such as automatic shutdowns and leak detection systems) must be integrated into the system.

-

Overpressure Protection: Hydrogen pipelines should include pressure relief devices to avoid catastrophic failures in the event of overpressure.

9. Hydrogen Gas vs. Liquid

-

Gas Pipelines: Typically used for medium to high-pressure applications, transporting gaseous hydrogen.

-

Cryogenic Pipelines: For transporting liquid hydrogen, which requires highly insulated pipes to keep the hydrogen at extremely low temperatures.

10. Hydrogen Distribution Networks

-

Hydrogen is transported through pipelines similar to natural gas but with different materials and configurations due to its distinct properties.

-

Dedicated hydrogen infrastructure (sometimes called “hydrogen corridors”) is being developed in various regions to supply industries, refueling stations for hydrogen vehicles, and even homes.

11. Applications of Hydrogen Pipelines

-

Fueling Stations: Pipelines transport hydrogen to refueling stations for fuel cell vehicles.

-

Industrial Use: Used in the chemical, refining, and manufacturing industries for processes like ammonia production or steel manufacturing.

-

Energy Systems: Hydrogen can be integrated into energy grids, acting as an energy carrier and storage medium.

-

Hydrogen Storage and Transport: Large-scale storage and transportation of hydrogen for later use in various applications.

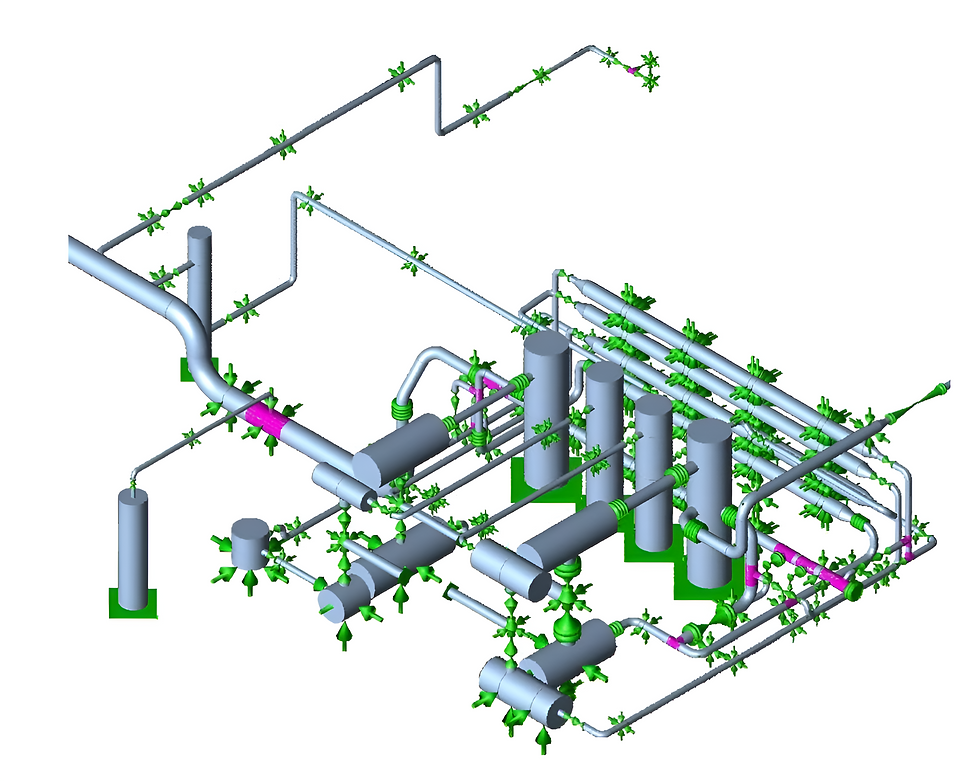

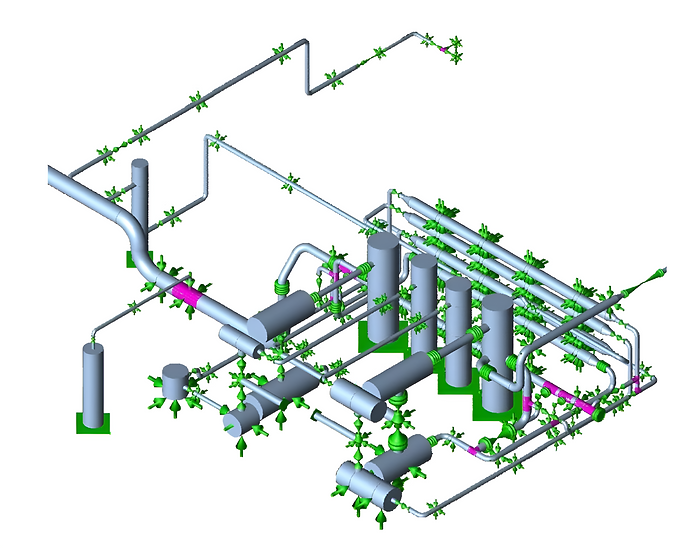

HYDROGEN PIPING DESIGN AND DRAFTING

Hydrogen Piping Design Services

Divya Engineering is a leading consultancy renowned for its expertise in the design and optimization of hydrogen piping systems. With a primary focus on industries where safety, reliability, and efficiency in transportation systems are paramount—such as hydrogen production, storage, power generation, and industrial applications—Divya Engineering offers a comprehensive range of services. These services include detailed CAD drawings, pipe stress analysis, 3D modeling, and the creation of fabrication and erection drawings. The company is committed to ensuring that each design maximizes performance, safety, and operational excellence, in full compliance with stringent industry standards like ASME B31.1 and ASME B31.3. Divya Engineering is also known for its innovative approach to piping layout optimization, stress analysis using advanced software like CAESAR II, and the development of Piping and Instrumentation Diagrams (P&IDs) for a broad array of industrial sectors.

HYDROGEN PIPING LAYOUT AND ROUTING

Hydrogen Piping Design and Engineering Expertise

Divya Engineering’s approach to hydrogen system design encompasses a wide range of specialized services necessary for creating safe, efficient, and reliable transportation systems. A crucial phase of the design process is the Piping Layout and Routing stage, where the team ensures that hydrogen systems are engineered to meet operational performance standards and meet strict safety requirements. Efficient layout planning is especially critical in sectors like industrial manufacturing, energy, and fuel processing, where the safe and effective transport of hydrogen is vital to operations. The company focuses on optimizing system designs to enhance both safety and ease of maintenance.

To achieve optimal results, Divya Engineering employs cutting-edge tools to model, visualize, and meticulously plan hydrogen piping systems for maximum accuracy.

HYDROGEN PIPING SUPPORT DESIGN

Piping Support Design

Piping Support Design is a key element in hydrogen piping systems, addressing the structural integrity of systems that may be exposed to high pressures, temperatures, mechanical stresses, vibrations, and potentially corrosive conditions. Divya Engineering’s expertise lies in designing robust supports, hangers, and brackets that secure piping systems and minimize the risk of failure. Using advanced stress analysis tools like CAESAR II and AutoCAD Plant 3D, along with BIM technologies like Revit, the company ensures that hydrogen piping systems are resilient and durable, even under demanding operating conditions.

HYDROGEN PIPING MATERIAL SELECTION

Material Selection for Hydrogen Systems

Material selection plays a crucial role in hydrogen system design to ensure long-term performance and reliability. Divya Engineering works closely with clients to select materials that can withstand the unique challenges presented by hydrogen, including extreme pressures, temperatures, and potential corrosive environments. Factors like pressure tolerance, temperature resistance, and corrosion resistance are carefully considered to ensure the system’s operational longevity and efficiency.

HYDROGEN PIPING STRESS ANALYSIS

Piping Stress Analysis and Compliance

Piping stress analysis is essential for systems designed to transport hydrogen, as these systems must endure pressure surges, thermal expansion, and external mechanical loads. Divya Engineering performs in-depth stress evaluations to ensure that hydrogen piping systems are both durable and safe, using advanced software like CAESAR II to simulate and analyze stresses on the piping systems. Compliance with industry standards is of utmost importance, and Divya Engineering adheres to the following guidelines:

-

ASME B31.3: Governs the design of process piping systems, ensuring they can safely transport fluids such as hydrogen.

ASME B31.1: Covers power piping systems, including those used to transport high-pressure and high-temperature fluids like hydrogen

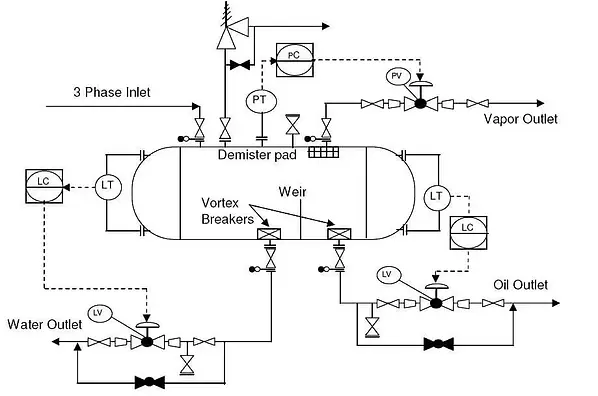

HYDROGEN PIPING AND INSTRUMENTATION DIAGRAMS (P&IDS):

P&IDs and Specification Development

Divya Engineering also provides comprehensive services in developing Piping and Instrumentation Diagrams (P&IDs) for hydrogen systems. These diagrams outline the layout and components of the piping system, including valves, pumps, instrumentation, and control systems. P&IDs are essential for simplifying maintenance and troubleshooting while ensuring safe operation. Additionally, Divya Engineering creates detailed piping specifications and standards that define the necessary parameters for installation, operation, and maintenance, ensuring compliance with both local and international safety and performance standards

HYDROGEN DEVELOPMENT OF PIPING SPECIFICATIONS AND STANDARDS

Divya Engineering offers services in developing Piping Specifications and Standards for high-pressure systems. They create detailed specifications and standards for piping materials, fabrication, and installation, ensuring consistency, quality, and compliance with industry regulations throughout the project lifecycle. Divya Engineering

Key Aspects of Their Piping Specifications and Standards Development:

-

Material Selection: Choosing appropriate materials based on factors such as fluid compatibility, operating temperature, pressure, and potential corrosion risks. Divya Engineering

-

Fabrication Guidelines: Establishing clear guidelines for the fabrication process to ensure that all components meet the required quality and performance standards.

-

Installation Procedures: Developing standardized installation procedures to maintain consistency and quality across all aspects of the piping system.

-

Compliance Assurance: Ensuring that all specifications and standards adhere to relevant industry codes and regulations, facilitating smooth project approvals and operational safety.

HYDROGEN PIPE SIZING AND HYDRAULIC CALCULATIONS

Advanced Modeling and Hydraulic Calculations

To optimize the efficiency and cost-effectiveness of hydrogen systems, Divya Engineering employs hydraulic calculations and advanced pipe-sizing techniques. These methods ensure that the system operates at peak performance while minimizing operational costs. By utilizing 3D modeling technology, Divya Engineering provides highly accurate visual representations of hydrogen piping systems, improving planning accuracy, reducing errors, and ensuring more reliable construction outcomes. The 3D modeling process minimizes risks associated with rework and facilitates smoother transitions from design to constructio

HYDROGEN 3D MODELING AND DESIGN

By utilizing 3D modeling technology, Divya Engineering provides highly accurate visual representations of hydrogen piping systems, improving planning accuracy, reducing errors, and ensuring more reliable construction outcomes. The 3D modeling process minimizes risks associated with rework and facilitates smoother transitions from design to construction.

HYDROGEN ISOMETRIC/FABRICATION/ERECTION DRAWINGS

Isometric, Fabrication, and Erection Drawings

Once the design phase is completed, Divya Engineering generates a comprehensive set of Isometric Drawings, Fabrication Drawings, and Erection Drawings. These drawings are essential for the precise construction and installation of hydrogen systems, ensuring that each component is fabricated, assembled, and installed according to the specifications. Isometric drawings provide a 3D perspective of the system, fabrication drawings detail the individual components and materials, and erection drawings guide the on-site assembly process, ensuring the final installation matches the original design.

By offering these full-service capabilities, Divya Engineering guarantees the successful design, implementation, and operation of hydrogen piping systems that are safe, reliable, and efficient, even in demanding industrial environments. Their unwavering commitment to quality, innovation, and compliance ensures that each transportation system meets the highest standards of safety and operational excellence.

Hydrogen Piping Design Services

Piping Design Consultants- Hydrogen Piping | Divya Engineering

Piping Design and Drafting: Creating detailed CAD drawings and design calculations for Hydrogen piping systems used in power plants, refineries, and other industrial facilities.

Pipe Stress Analysis: Performing static and dynamic stress analysis using software like CAESAR II to ensure the Hydrogen piping system can withstand operational and environmental stresses.

3D Modeling and Design: Using software such as PDS, PDMS, or Auto Plant to create 3D models of Hydrogen piping systems for better visualization and accuracy.

Isometric/Fabrication/Erection Drawings: Preparing detailed drawings for the fabrication and installation of Hydrogen piping systems.

Support Detail Drawing Preparation: Designing and detailing the necessary supports for the Hydrogen piping system to ensure stability and safety.

Project Management: Managing the entire Hydrogen piping design project from initial conceptualization through fabrication and commissioning.

Compliance with Standards: Ensuring that the design complies with relevant standards such as ASME B31.1 for power piping and ASME B31.3 for process piping.

BILL OF MATERIAL, INSULATION & EXPANSION JOINTS

Challenges Hydrogen piping design

Designing hydrogen piping systems presents unique and complex challenges due to the flammability, reactivity, and other specific properties of hydrogen gas. These challenges must be carefully addressed to ensure the safe and efficient transportation and handling of hydrogen. Below are the key challenges in hydrogen piping system design:

1. Hydrogen Embrittlement:

Hydrogen has a tendency to cause embrittlement of metals, especially in high-pressure environments. When hydrogen permeates the metal, it can cause it to become brittle, leading to cracks and eventual failure of the piping system. Material selection is critical in preventing hydrogen embrittlement. Designers must choose materials that are resistant to this phenomenon, such as certain stainless steels, high-strength alloys, and composites. Regular inspections and maintenance are also required to monitor the condition of the system.

2. Flammability and Explosion Risk:

Hydrogen is highly flammable and has a wide range of flammability in air (from 4% to 75% by volume). Even small leaks can present significant fire and explosion hazards. Therefore, hydrogen piping systems must be designed with extreme care to prevent leaks, using high-quality seals, joints, and connections. Specialized safety features such as explosion vents, flame arrestors, and emergency shutoff valves are essential in reducing the risk of ignition. Leak detection and mitigation systems must also be integrated to quickly identify and address any leaks.

3. Leakage and Detection:

Hydrogen molecules are the smallest and lightest, which makes hydrogen prone to escaping through tiny leaks, even in systems with high-quality seals and fittings. Hydrogen is also colorless, odorless, and tasteless, making it difficult to detect without the use of specialized sensors. Therefore, hydrogen piping systems require advanced leak detection technologies, such as hydrogen-specific sensors, continuous monitoring, and visual inspection programs to identify any leaks early before they become dangerous.

4. High Pressure and Pressure Control:

Hydrogen is often stored and transported at very high pressures (up to 700 bar or higher), which can place significant stress on the piping system. Over-pressurization can lead to catastrophic failures such as bursts or leaks. Piping systems must be designed with proper pressure control, including regulators, pressure relief valves, and safety valves, to maintain safe operational limits. In addition, the pressure rating of materials and components must be carefully selected to withstand the high-pressure conditions without failure.

5. Thermal Expansion and Contraction:

Hydrogen systems may operate under extreme temperature variations, including cryogenic temperatures when hydrogen is in liquid form or during changes in ambient temperature. Hydrogen has a low boiling point (around -253°C), which presents challenges when designing cryogenic systems. The expansion and contraction of hydrogen piping due to temperature fluctuations can lead to mechanical stress, leaks, or failure if the system is not properly designed to accommodate these changes. Designers must incorporate expansion loops, insulation, and flexible joints to prevent these issues.

6. Material Compatibility:

Hydrogen can interact with certain materials in unintended ways, causing corrosion or material degradation. Piping materials must be carefully selected to ensure compatibility with hydrogen and to prevent issues such as hydrogen-induced cracking or stress corrosion. Materials like carbon steel are generally not suitable for hydrogen transportation due to their susceptibility to embrittlement, while specialized alloys such as duplex stainless steel, monel, or nickel-based alloys are often preferred for their resistance to corrosion and embrittlement. Surface treatments and coatings may also be needed to enhance material performance.

7. Vibration and Mechanical Stress:

The pumps and compressors used to move hydrogen through piping systems can generate significant vibrations. Over time, mechanical vibrations can lead to fatigue in piping and components, which can result in leaks or failure at vulnerable points, such as joints and fittings. It is essential to design the system with adequate supports, brackets, and damping systems to minimize vibration-induced stresses and prevent system damage.

8. Hydrogen Permeability:

Hydrogen is known to permeate through many materials over time, particularly metals. This characteristic can result in hydrogen loss or leaks, even in well-sealed piping systems. Designers need to account for this by selecting materials with lower hydrogen permeability and incorporating protective measures to prevent permeation. For instance, materials like high-density polyethylene (HDPE) or composite piping may be used in certain applications to reduce permeation risks.

9. Safety and Regulatory Compliance:

Hydrogen systems are subject to strict safety standards and regulations, given the inherent risks associated with handling a flammable gas. Compliance with standards set by organizations such as the National Fire Protection Association (NFPA), American Society of Mechanical Engineers (ASME), and other regulatory bodies is essential. Designers must ensure that the hydrogen piping system adheres to safety protocols, including the use of approved components, safety measures, and inspection procedures to minimize risks during both normal operation and emergency situations.

10. Hydrogen Containment and Storage:

Safe containment and storage of hydrogen require specialized equipment, including high-pressure vessels, tanks, and safe storage environments. The design must integrate these elements into the overall hydrogen piping system to ensure a secure and efficient supply of hydrogen. The piping system should allow for easy connection to storage units, with provisions for pressure regulation, and ensure that hydrogen is safely and efficiently transferred to where it is needed.

11. Cryogenic and Ambient Temperature Challenges:

Hydrogen can be transported in both gaseous and liquid forms, depending on the application. When transporting liquid hydrogen (LH2), extremely low temperatures are required, presenting challenges such as cryogenic piping design, insulation, and handling. Liquid hydrogen must be maintained at temperatures around -253°C (-423°F), which demands the use of special materials and highly insulated pipes to prevent boil-off and ensure energy efficiency. For gaseous hydrogen, the temperature and pressure variations in ambient conditions can affect system efficiency and performance.

12. Cost Management:

Hydrogen systems often require specialized components, such as high-strength alloys, seals, and cryogenic materials, which can significantly increase the cost of the piping system. Managing the cost while ensuring that the system is designed to be both safe and reliable is a challenge. Designers must find cost-effective solutions that do not compromise safety or system performance while meeting the operational requirements of the project.

13. System Integration and Complexity:

Hydrogen piping systems often need to integrate with other infrastructure, such as compressors, storage units, fueling stations, and energy generation systems (e.g., fuel cells). Each component must be compatible with the rest of the system, and the overall design must be optimized to ensure seamless operation. This adds a layer of complexity to the design process, as coordination across different engineering disciplines is required to meet all performance, safety, and regulatory standards.

Conclusion:

The design of hydrogen piping systems is complex and requires specialized knowledge and expertise to address the unique challenges posed by hydrogen’s physical properties. Ensuring safety, preventing leaks, managing pressure and temperature, and selecting compatible materials are key factors in achieving reliable and efficient hydrogen transportation systems. By addressing these challenges through advanced engineering practices, careful material selection, and compliance with safety standards, it is possible to design hydrogen piping systems that provide long-term performance and minimize risks.